1. Introduction of Radial Sintered NdFeB Ring Magnet for Motor

Radial Sintered NdFeB Ring Magnet is developed to meet different requirements of permanent magnet servo motor, using the new shaping method by multipole polymerization radial orientation.

The products can be widely used in:

(1) Spindle motor for HDDs(Hard Disc Drive), FDDs (Floppy Disc. Drive); all kinds of permanent magnet Servomotors for robots, machinery; step motor.

(2) Tachogenerators

(3) EPS (Electronic Power Steering System in automobiles), etc.

(4) Actuators.

Compared with segments jointed ring, radial ring magnet can improve the output characteristics and significantly reduce the loss of motor, it has excellent temperature stability, corrosion resistance and temporal stability ,and so on, especially applying for high precision micro & special motor drive.

| Outer Diameter(OD) | Inner Diameter(ID) | Thickness | Height | Coating | BH(max) |

| Max 150mm | Min 10mm | Min 2mm | Max 50mm | Ni / Zn / Epoxy | 35·50 MGOe |

|

|

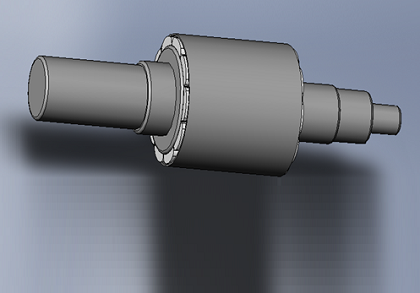

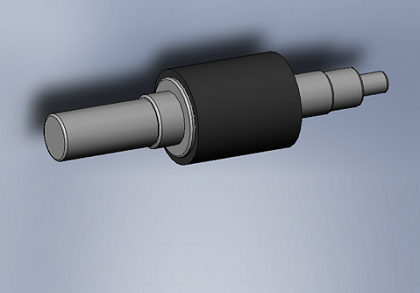

| Item | Ring jointed by the segments | Radial ring( A complete ring) | |

| Construction | Several segment magnets joint into a ring, then add a protecting cover. | The radial ring assemblize on the bearing directly, no need to add the protecting cover, simple and quick. | |

| Appearance Precision | Assembling by the protecting cover, bearing and several segment magnets, hawing the lower precision. | Radial ring directly determines the shape tolerance, the tolerance of outer and inner diameter can achieve +/-0.3mm, and has the good coaxiality and verticality. | |

| Reliability | In some cases, the segments will break away from the bearing. | Simple mechanism and good reliability | |

2. Physical Properties

| Density | ρ | 7.6 | g/cm3 |

| Vicker Hardness | 600 | HV | |

| Modulus of Elasticity | E | 150 | Kn/mm2 |

| Compressive Strength | 1000 | N/mm2 | |

| Tensile Strength | 78 | N/mm2 | |

| Flexural Strength | 245 | N/mm2 | |

| Expansion Coeff. | ⊥ρ.ρ.d | -1 | 10-6/K |

| ∥ρ.ρ.d | 5 | 10-6/K | |

| Spec.Elec.Resistance | ρcl | 1.45 | 10-6Ω·m |

| Spec.Heat Capacity | c | 440 | J/(kg·K) |

| Thermal Conductivity | λ | 8 | W/m·K |

Features:

(1) The cylindrical shape enables higher precision in external dimensions.

(2) As a rotor, can achieve uniform magnetic density flux distribution.

(3) Fastening the magnet is simple, enabling assembly-related cost reductions.

(4) Highly reliability due to enabling rotor construction from a single magnet.

(5) Optional magnetization, including free multiple magnetization, skew-type magnetization possible (Radial anisotropic magnet)

(6) Can obtain sine surface inductive flux distribution (multi-pole oriented magnet)

3. Curve:

4. Magnetic Properties

We have currently the grades as following chart.

| Grade | Remanence | Coercive Force | Intrisinc Coercive Force | Max. Energy | Working Temp. |

| Br(Gs) | Hcb(Oe) | Hcj(Oe) | (BH)max | TW* (℃) | |

| 35H | 11500-12300 | 10500 | 15500 | 30-35(MGOe) | 120 |

| 40H | 12200-13100 | 11000 | 15500 | 34-40(MGOe) | 120 |

| 45H | 12600-13800 | 12000 | 15500 | 37-45(MGOe) | 120 |

| 38M | 11800-12800 | 9800 | 13500 | 32-38(MGOe) | 120 |

| 35SH | 11500-12300 | 11500 | 18500 | 30-35(MGOe) | 150 |

| 38SH | 11800-12800 | 11500 | 18500 | 32-38(MGOe) | 150 |

| 42SH | 12300-13400 | 11500 | 18500 | 35-42(MGOe) | 150 |

| 35UH | 11500-12300 | 10500 | 23500 | 30-35(MGOe) | 180 |

| 40UH | 12200-13100 | 11000 | 23500 | 34-40(MGOe) | 180 |